Mechanical properties of printed ABS & it’s relation

to the structure & defects in the printed material

Introduction

The main goal of this research is to discover the relation between the mechanical properties

of the printed ABS to the defects in the printed material by the printing parameters and

building orientations and building strategy.

The strength of FFF printed ABS is composed of at least four components – The welding

strength between printed layers, the welding strength between the wires in each layer, the

wires’ strength and the cavities created during the printing process. In order to improve the

understanding of designing products with mechanical requirements before printing for

preventing failures.

Experimental Method

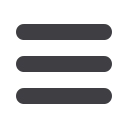

For this study, three-points bending specimens were

printed according to ASTM D790 at the dimension of

3.2(mm)X12.7(mm)X127(mm) using a Stratasys

Dimension Elite FFF printer which located at ‘Afeka’

College (printing process described at Fig .2).

Samples of different building strategy and building

angle were printed and given different names

simplified according to ASTM ISO ASTM 52921 (Fig.1).

Each sample was measured for geometric dimensions

and for mass, then absolute density was calculated,

then divided by 1.04 (gr/cc) (the ABS density which provided

by ‘Stratasys’) in order to calculate relative

density. After the nondestructive test, the

samples were then bent at bending

machine of ‘MTS’ Exceed Model E43 for

axial deflection and strength.

Then flexural strength was calculated.

Fractography analysis was conducted to

the fractured samples.

Or Gewelber

Advisor: Professor Adin Stern

Mechanical Engineering

The first two trays are identical and each of them

has eighteen three-point bending flexural test

ABS specimens that were 3D-printed at six

different orientations (Fig. 3). Twelfth three-point

bending flexural test ABS specimens were

3D-printed in the third tray at two orientaions:

Each of these groups were divided to two:

(1) specimens that were bent next to the build

platform, and (2) specimens were bent far from

the build platform, With the purpose to examine

if there is a change of the mechanical propeties

because of the build platform heating gradient.

Results and conclusions

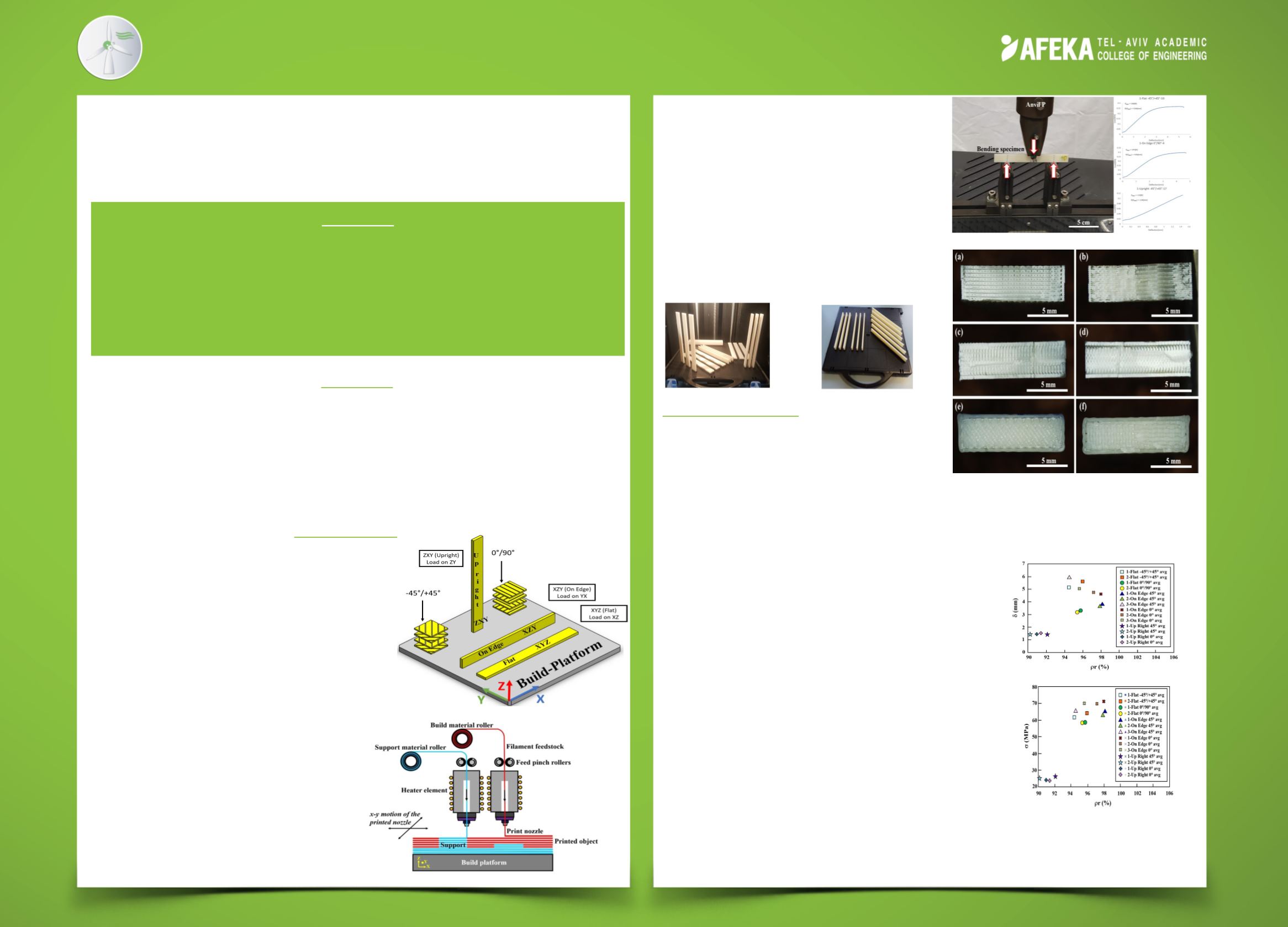

Based on the three point bending testing results,

it was found that the specimen with the highest

amount of flexural strength is not necessarily the

one with the highest deflection. It was also

observed that On Edge 0°/+90° orientations

shown relatively larger flexural strength difference

in comparison to other building orientations

(Flat and Upright).

Relative density measurements were measured

from mass and geometry tests and then compared

with the manufacture. Average Upright samples

were with the range of 88.67÷92.09[%] against

Flat and On Edge sample that were with average

of 94.41÷98.1[%].

When Comparing deflection between different

groups of the same orientation comes the

realization that there is no dominance to any

orientation, which can be explained by the uneven melting

of the fibers permitting the option of uneven deflection and

structural defects that cause longer movement.

tray’s three data correlate to the data of the first two trays,

while regarding the side of bending, lack of trend appears ,

so it can be said that it doesn’t matter to bend at the area

of creation of the sample or at the area of the ending of

the creation.

From the fractography there is a lack of overlap between

the contour to the interior, that is an area without

melting that cause many defects.

Abstract

One of the main Additive Manufacturing (AM) technologies

is the Fused Filament Fabrication (FFF), in which layers of

molten wires of thermoplastic polymers are extruded in

order to form 3D objects. Mechanical properties and defects

can be changed by different building orientations.

Figure 1

Figure 2

Figure 3

Figure 4

(a)

(b)

Figure 7:ABS 3D-printed three-point

bending experimental results of the Flat,

On Edge and Upright configurations:

(a) density vs. deflection; and (b) density

vs. flexural strength

Figure 6: The fracture surfaces of the ABS printed

specimens after the three-points bending tests:

(a) 1-Flat 0°/90° -2 specimen; (b) 1-Flat -45°/+45° -10

specimen; (c) 1-On Edge -45°/+45° -12 specimen; (d)

1- On Edge 0°/90° -4 specimen; (e)1-Upright -45°/-

45°-17;(f)1Upright 0°/90°-14

Figure 5