Wrist Implant

Abstract

This project is a research project that directly continues three previous ones that were

conducted by research groups in past classes.

The goal of this study is to solve an existing problem in the hand implants market,

which currently does not provide a satisfactory solution. The most common wrist

problems are luxation, fractures, and arthritis.

These problems often result from overexertion, incorrect use of the joint, and external

traumas. As a result, the joint bones move, causing osteoarthritis, pain, and impaired

function. Therefor, there is a need to replace the wrist with an implant.

The main problem with the implants is that the connection between the implant and the

bones loosens after a few short years

.

As a result, in this project, we will conduct an in-depth investigation of the

biomechanics that exists at the connection point between the implant and the bones.

Also, because modeling the wrist and the forces that affect it is difficult, we have

chosen to abandon the experimental model. Moreover, the information that could have

been produced would have been scant and irrelevant

.

Research method

In this project

,

we will deal with a numerical research method. we carried out strength

analyses via the ABQUS software for several wrist positions using the most advanced

implant currently available in the market

–

MWP (Motec) by Swemac

.

In addition we will

perform three analyzes on three implants that we designed

Eyal Avisar, Hanoch Francis

Advisor: Dr

.

Moshe Brand

Client: Dr

.

Amir Arami

Mechanical Engineering

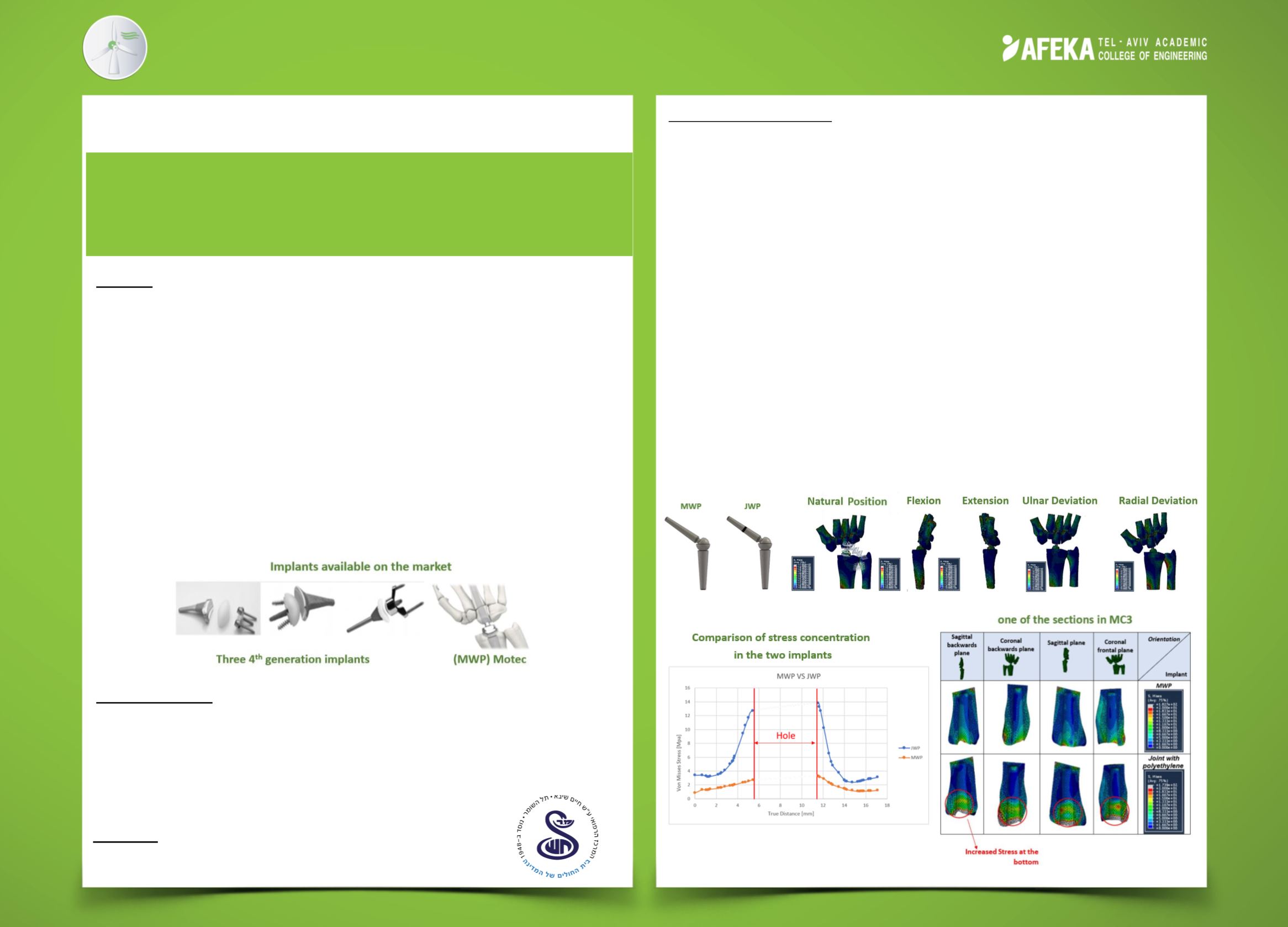

Results and conclusions

Following the analyses and after consulting various sources, we conclude that:

We should focus on the wrist's natural position, as there are no significant

differences between the stresses that are produced in different positions.

The problem with the current implant is low stresses in the drilling envelope - at the

connection point between the implant and the bones - which causes reduced bone

formation. Therefore, it is necessary to increase the stress in these areas, which in

turn will increase bone growth based on Wolff's law, as will be detailed later on.

Micro-motions occur throughout the implant, especially in its apex, causing it to

loosen.

For these reasons, in this project, we designed three implants that increase the stress

in areas that have been identified as problematic

.

We conducted three different

analyses on these implants and analyzed their results.

The results of the analyses strongly suggest that the JWP increases the stresses

significantly compared to the other implants.

Throughout the project, we carried out ten strength analyses on four potential

implants. We conducted an in-depth investigation of the stress on the drilling envelope

at the connection point between the implant and the bones. Furthermore, we came up

with possible solutions for the development of alternative implants that would provide

better outcomes

.

The client

Dr

.

Amir Arami

,

specialist in orthopedic surgery and in particular

hand surgery, at Sheba Hospital

,

Tel Hashomer

.

Perform numerical analyzes using software for finite elements

on an existing MWP implant and examine the evolving stress

between the implant and the bone and following the results

design a new implant